| |

|

|

| » |

Water Cooled Sub / Jumper Cable ( An ISO 9001:2008 Certified Company ) |

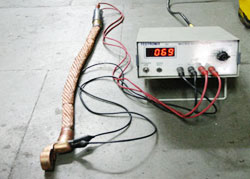

| Resistance checking of Aid/Sub Cable |

Water - Cooled Aid/Sub Cable Final Packing Process |

|

|

|

|

These cables are used as supplementary cable to connect kickless cable and gun are of the single conductor only. To meet the connector needs in the resistance welding operation. Electromech offer a broad variety of secondary cable. Each cable is design and built to perform with maximum efficiency and economy in its in depended application. Electromech water-cooled jumper (Aid)cable to electrically connect distant points which move in relation to each other such as, |

The movable gun-arm of the certain types of welding guns to the electromech cable. |

| On a multiple spot welding machines. |

Electromech water cooled jumper & sub cables are flexible rope types secondary connectors, assembling with high conductivity terminals. There are sheathed with reinforced abrasion & oil resistant hose. Free water passage is insured by means of an open spring core progressing the entire length of the cable. Thus permitting the cable to operate under the condition of acute bending without obstructing the water flow. |

| |

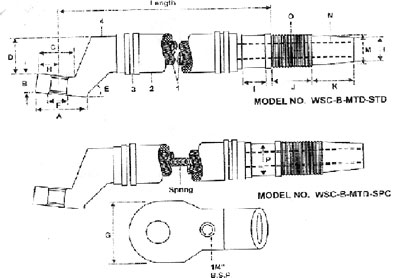

WATER COOLED SUB/JUMPER CABLE SINGLLE

CORE CABLE ONE END MALE THREADED |

|

| FLEX ‘CU’ BRAIDED WIRE. |

| OUTER COVER RUBBER HOSE |

| HOSE CLAMPES |

HIGH CONDUCTIVITY COPPER TERMINAL |

|

| HOW TO ORDER ELECTROMECH KICKLESS CABLE |

| Please supply the following information. |

| Sl. No. |

MCM / MM2 |

DIAMENSIONS IN MM |

| Bendend |

Male threaded end |

| E.g. |

300mcm / 150 mm2 |

Length ‘a’ ‘b’ ‘c’ ‘d’ ‘e’ ‘f’ ‘g’ ‘h |

I’ ‘j’ ‘k’ ‘l’ ‘m’ ‘n’ ‘o’ ‘p’ |

| |

|

1000 58 15 45 50 81o ǿ17 |

16 25 25 ǿ19 ǿ20 ½ “ 26x10 SW TPI |

| 1 |

|

|

|

| 2 |

|

|

|

|

| |

| TERMINALS |

Straight lugs are machined from high conductivity electrolytic Copper bar stock. |

Bends lugs are forged and machine from high conductivity electrolytic copper. |

| |

| WIRE CONSTRUCTION |

This is a made from 0.05mm2 electrolytic grade Copper wire. Each bunch or herringbone construction to reduce the rate of wire facture by providing lateral surfaces wears areas. The total sectional area shall not be less than the sectional area as per MCM/mm2 rating. |

| |

| Wire connection to terminal |

Water is terminated in a crimped in soft electrolytic tube and the soldered to the terminals. |

| Wire cannot melt out during brief overloads |

| |

| FLEXIBLE HOSE COVER |

| The outer rubber hose made of heat resistant on its inner Surfaces & abrasion resident on its outer surfaces. |

| |

| WATER FLOW |

| Coiling water is passed at the rate of 3 lit/ min at the pressure of the 6kgf/ cm2 and the pressure drop does not exceed 0.7kg/ cm2 |

| |

| WATER PRESSURE |

The cable is tested at a pressure of 6 kgf/ cm2 (kcs) to ensure then there is no leakage or hose damage. |

| |

| Optional feature |

| ROTECTION SLEEVES: - In order to eliminate breakage of strands due to frequent acute bending operation, projection sleeves are provided on the area of both the terminal joints. |

| |

Water Cooled Sub (Aid) Cable – Technical Parameter chart |

Specification |

Length |

180 mm2 (360 mcm) |

Remarks |

d.c resistance

at 25o c |

1.0 m |

Below 110 micro ohms |

|

1.5m |

Below 165 micro ohms |

Coolant

Flow rate |

1.0 m |

More than 3 lit/ min |

Pressure loss 0.5 kgf / cm2 |

1.5 m |

More than 3 lit / min |

Temp rise of coolant |

1.0 m |

46o c at 6600 amp count. |

At coolant flow rate of 7 lit /min |

1.5 m |

47o c 5700 amp count |

Weight |

1.0 m |

3.5 kg. approx |

|

|

| |

Special type flexible Rubber Hose and Star separator is non conductive heat & oil resistance and hardness 50 to 60 degree Shore A. Over all finished Cable flexibility checked by the coiling around wooden former. |

| |